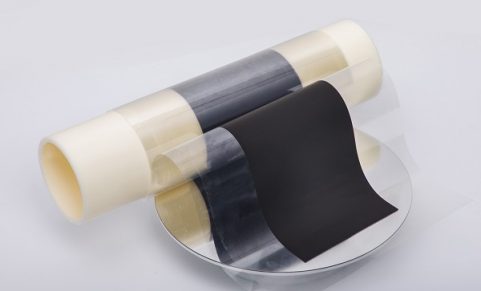

At SinoHyKey, we know that quality is your priority, too: that’s why we custom design the catalyst mixture, ink formulation, and process parameters for every client’s unique CCM to ensure unrivaled performance and reliability. Our automated production line features a slot-die mechanism that uses patch/intermittent and stripe coating technologies for laser-precise application; a computerized inspection stage quickly and accurately points out any flaws that might arise during the previous steps. Our CCMs are built to thrive in the extreme operating conditions of a fuel cell vehicle, where temperature and humidity fluctuations, as well as frequent start/stop cycles, present a need for more robust components.

Products

CCM

It is possible to integrate OER (oxygen evolution reaction) technology into our CCMs; for more details, please see the Technology section of our website.

CCM production specs:

| Roll-to-roll Capacity | > 300,000 | m2 annually |

| Line Speed | > 3.0 | linear meters per minute |

| Maximum Coating Size | 400 x 280 | mm |

| Cathode and Anode Edge Overlapping Tolerance | < 0.5 | mm |

A SinoHyKey patch coated CCM roll

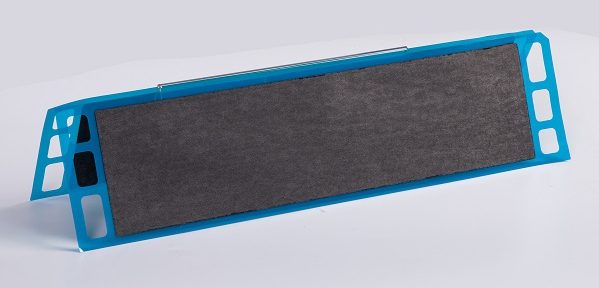

MEA

SinoHyKey offers customizable framed MEAs, with accelerated delivery schedules (of up to 300,000 m2 per year) made possible by our quick-turnaround production methods. We currently operate two MEA production lines, with another on the way:

- A highly flexible manual line, suitable for prototyping and low volume production

- A medium volume semi-automated line, for manufacturing tested MEA designs

- A high-volume roll-based mass-production line to meet the MEA requirements for commercialized programs (work in progress)

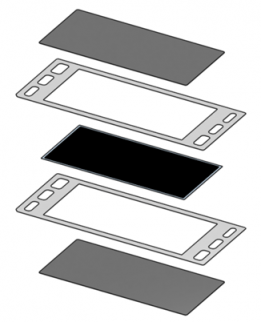

Currently, SinoHyKey’s MEAs are typically of the double frame format, where a single CCM is sandwiched between two frames. This tried and proven method is a cornerstone of our company’s offerings, but we are also developing a single frame variant which will serve to reduce the amount of frame material used in an MEA, thereby cutting down on costs and simplifying the manufacturing process.

Left to right: double and single frame MEA

Customization

SinoHyKey is capable of rapid in-house CCM/MEA prototyping, allowing us to design and test a product that’s compatible with your applications; after taking into consideration the required output and specific operating conditions of your fuel cell stack, we can decide on a set of target parameters and configure a prototype that meets them. Employing the principles of design for manufacturing (DFM), we streamline our model to fulfill these needs at the necessary production volume and with minimal waste. After the prototype passes rigorous quality and performance assessments, we proceed with full-scale manufacturing.

Performance

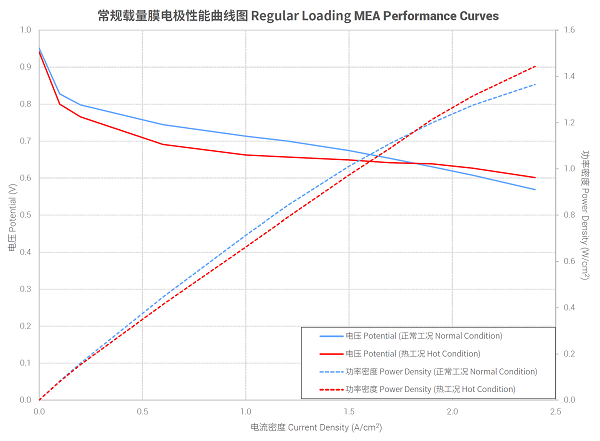

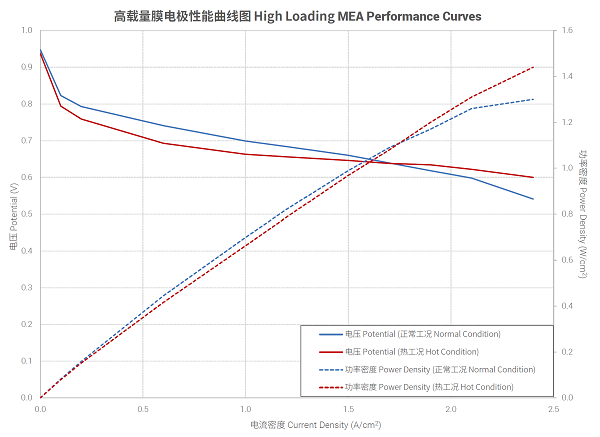

When operating at 1.5 A/cm2, our MEAs possess typical power densities exceeding 1 W/cm2, with some able to reach 1.4 W/cm2; combined with exceptional longevity and extended BOL reversal tolerances of up to 120 minutes, we are proud to offer MEA products with unparalleled capabilities.

A generic MEA by SinoHyKey

One of the most expensive aspects of a fuel cell is the catalyst, typically consisting of a precious metal like platinum; substantial electrical loads require a thicker catalyst layer, thereby increasing the costs of manufacturing. Through market analysis, we’ve determined that in order to make our products more affordable, it would be optimal to offer two types of MEAs to suit different loadings:

Regular loading: for less demanding applications, like passenger vehicles, UAVs, or forklifts

High loading: for commercial and other heavy-duty vehicles

Regular loading MEA performance curves

High loading MEA performance curves